PA Based Silicone Masterbatch diminye koyefisyan friksyon an epi amelyore rezistans mete a.

PA Based Silicone Masterbatch te redwi koyefisyan friksyon an epi li te amelyore rezistans mete a,

epi diminye tan sik la, pi bon ranpli mwazi, pi bon glisman sifas, pi fasil pou lage mwazi, santiman men, Amelyorasyon koule fonn, Amelyore rezistans a reyur ak mete, mwens konsomasyon enèji, Pi ba koyefisyan friksyon, pi ba koupl èkstrudè, Mèt batch silikon ki baze sou PA, presyon mwazi redwi ak bave mwazi,

Deskripsyon

Silikon Masterbatch (Siloxane Masterbatch) LYSI-307 se yon fòmilasyon pellet ak 50% polymère siloxane ultra wo pwa molekilè dispèse nan Polyamid-6 (PA6). Li lajman itilize kòm yon aditif pwosesis efikas nan sistèm résine konpatib PA pou amelyore pwopriyete pwosesis yo epi modifye kalite sifas la.

Konpare ak aditif silikon/siloksan konvansyonèl ki gen pi ba pwa molekilè, tankou lwil silikon, likid silikon oswa lòt kalite polimè silikon, seri SILIKE Silicone Masterbatch LYSI yo espere bay pi bon benefis, pa egzanp, mwens glise vis, pi bon dekoleksyon mwazi, diminye bave mwazi, yon koyefisyan friksyon ki pi ba, mwens pwoblèm penti ak enprime, ak yon pi gwo seri kapasite pèfòmans.

Paramèt Fondamantal yo

| Klas | LYSI-307 |

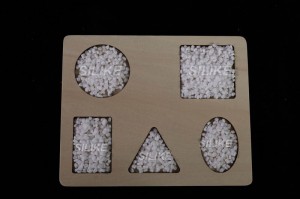

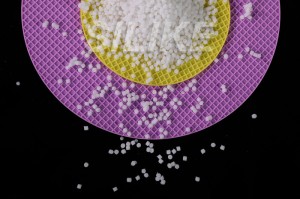

| Aparans | Granul blan |

| Kontni silikon (%) | 50 |

| Baz résine | PA6 |

| Endis fonn (230 ℃, 2.16 KG) g/10 min | 36.0 (valè tipik) |

| Dòz % (p/p) | 0.5 ~ 5 |

Benefis

(1) Amelyore pwopriyete pwosesis yo tankou pi bon kapasite koule, mwens bave nan mwazi èkstruzyon, mwens koupl èkstrudè, pi bon ranpli ak lage bòdi.

(2) Amelyore kalite sifas la tankou glisman sifas la, pi ba koyefisyan friksyon an.

(3) Pi gwo rezistans fwotman ak reyur

(4) Pi rapid debi, diminye pousantaj domaj pwodwi.

(5) Amelyore estabilite konpare ak èd pwosesis tradisyonèl oswa lubrifyan

Aplikasyon yo

(1) Konpoze PA6, PA66

(2) Konpoze PA fib vè

(3) Plastik jeni

(4) Lòt sistèm konpatib ak PA

Kijan pou itilize

Yo ka trete masterbatch silikon seri SILIKE LYSI a menm jan ak résine yo itilize a. Yo ka itilize li nan pwosesis melanj klasik tankou èkstrudè vis senp/doub, bòdi piki. Yo rekòmande yon melanj fizik ak granules polymère vyèj. Pou pi bon rezilta, yo rekòmande yon pre-sechaj pandan 3 ~ 4 èdtan nan 80 ~ 90 ℃.

Dòz rekòmande

Lè yo ajoute l nan PA oswa yon tèrmoplastik menm jan an nan yon pwopòsyon 0.2 a 1%, yo espere yon amelyorasyon nan pwosesis la ak nan koule résine a, tankou pi bon ranpli mwazi a, mwens koupl nan èkstrudè a, lubrifyan entèn yo, degajman mwazi a ak yon débit ki pi rapid; Nan yon nivo adisyon ki pi wo, 2 a 5%, yo espere yon amelyorasyon nan pwopriyete sifas yo, tankou lubrifyan, glisman, pi ba koyefisyan friksyon ak pi gwo rezistans kont mak/grafouyen ak fwotman.

Pakè

25Kg / sak, sak papye atizanal

Depo

Transpòte kòm yon pwodui chimik ki pa danjere. Sere nan yon kote ki fre epi byen ayere.

Lavi etajè

Karakteristik orijinal yo rete entak pandan 24 mwa apati dat pwodiksyon an, si yo konsève nan depo rekòmande a.

Chengdu Silike Technology Co., Ltd is a manufacturer and supplier of silicone material, who has dedicated to R&D of the combination of Silicone with thermoplastics for 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnSilike silicone masterbatch LYSI-307, PA Based Silicone Masterbatch, used as an efficient agent in PA resins and glass fiber-reinforced PA compounds, significantly reduced the coefficient of friction and improved wear resistance at lower loadings than PTFE while retaining important mechanical properties. It also additives in processing efficiency and improves material injectability. Besides, helps finished components deliver scratch resistance while enhancing surface quality. In contrast to PTFE, silicone additive avoids the use of fluorine, a potential medium- and long-term toxicity concern. as well as silicone additive comes with doing something environmentally sound.

ADITIF SILIKÒN GRATIS AK ECHANTIYON Si-TPV PLIS KE 100 KLAS

Kalite echantiyon

$0

- 50+

klas silikon mètbatch

- 10+

klas poud silikon

- 10+

klas Anti-grafouyen Masterbatch

- 10+

klas Anti-fwotman Masterbatch

- 10+

klas Si-TPV

- 8+

klas silikon sir

-

Telefòn

-

Imèl

-

Whatsapp

Whatsapp

-

Anlè

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur